Are all your prints starting to look the same? Are you seeking screen prints that’ll make your garments stand out and grab attention? If so, then maybe it’s time you tried PERMASET Aqua Puff Paste!

PERMASET Puff Paste is a special effects additive that contains a heat activated expanding agent. When mixed with ink, it will puff up once heated to a threshold temperature, giving prints a tactile and visual 3D effect. With this added volume, print designs will, quite literally, stand out.

When to use Puff Paste

PERMASET Puff Paste is often used in T-shirt printing to make designs more eye-catching. There are several ways that Puff Paste can enhance your special effects T-shirt designs:

- Puff can be used to highlight select elements of your design. For example, they could make a basketball ‘pop’ out of a sports logo, or your business name or logo stand out on a company shirt.

- Puff is also great for emphasising text. With PERMASET Puff Paste, printed text looks bolder and thicker and stand out from a larger design or other text that may be included in the design.

- Puff Paste allows you to accent certain details of a one colour design, adding textural interest to select elements of the design.

- To enhance graphic effects of pattern and repetition, your custom T-shirt will have a unique look and feel when Puff Paste is used to add texture to dots, squares or other shapes.

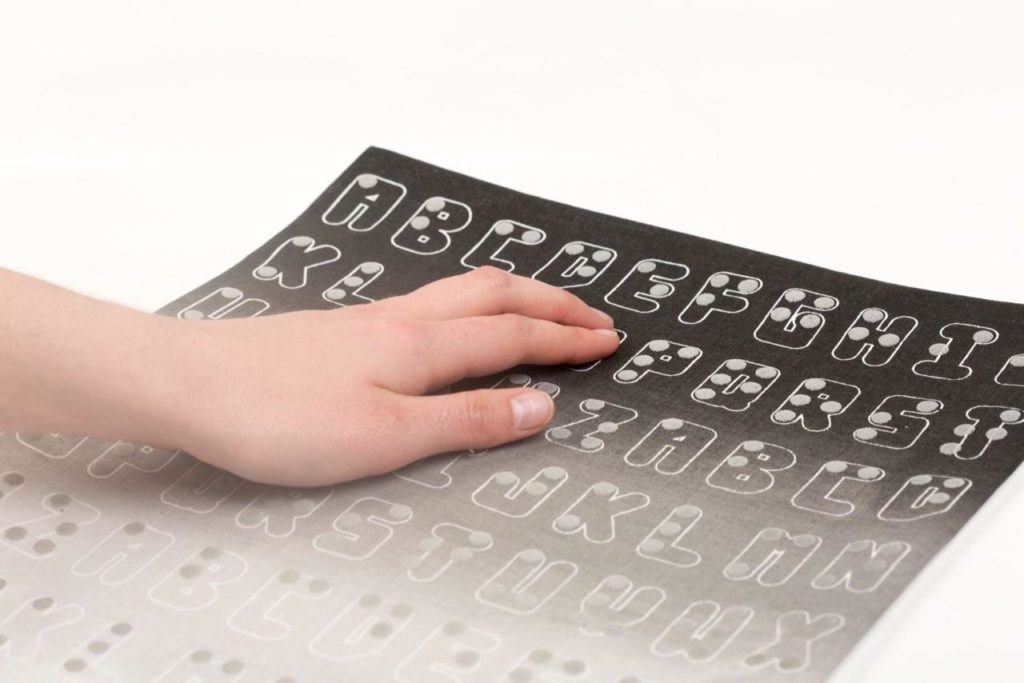

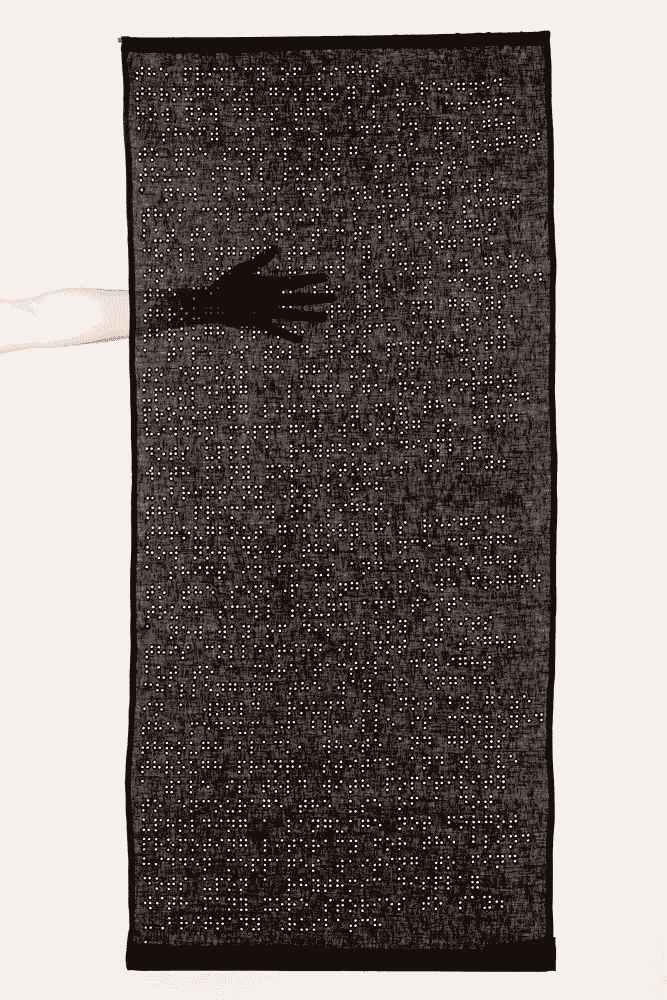

- Puff Paste has also been used for decades by the Royal Blind Society to print Braille for the visually impaired. The tactile properties of PERMASET Puff prints are demonstrated in these Braille designs by Massey University NZ student Brittany Rusbatch. How amazing are these?

How to use PERMASET Puff Paste

There is a small difference between screen printing with regular PERMASET Inks and printing with Puff Paste; you do have to be a little more careful. First up, you’ll need to ensure that you add the right amount of paste to your ink, although generally more paste will result in a puffier design. You also might need to lay down a little more ink than usual to get a good 3D effect and that in turn will be helped by applying through a thicker stencil (more coats of emulsion during screen prep) and/or lower mesh count screens.

Other things you should be aware of when using PERMASET Puff Paste include:

- Make sure that the Puff Paste is mixed thoroughly with your ink before printing.

- Don’t use Puff Paste if your design includes really intricate details. Fine detail will be lost once the ink puffs up.

- Don’t use Puff Paste if you need precise edge definition to your design or for colours abutting each other in a design. The fine edge between two colours will be lost to the puff effect.

- Expect some colour loss. Because Puff Paste is an additive, it will dilute the colour of your ink. Prepare for this by starting with a slightly bolder colour than the one you intended to use.

- PERMASET Puff Paste will result in a matte finish, so if you’d prefer a glossier finish, then you should seek other options.

- Because of its physical bulk, PERMASET Puff prints will distort or cockle light weight fabrics like silk and organza once heat activated.

- Designs including large continuous shapes printed with Puff will also be prone to distortion or cockling. This can be alleviated to some degree by making up the overall shape via an assemblage of smaller discontinuous dots. These will appear separate on printing, but will merge together once heat activated.

- Always run a test print first!

Curing your PERMASET Puff Print

Once you’re done printing, allow the garment to dry for at least 15 minutes to let the paste dry before curing. Curing should be done using an oven for around 4-5 minutes at 160 °C (320 °F). Curing at the specific temperature and for the correct amount of time is crucial when using PERMASET Puff Paste. Too little or too much of either can lead to inadequate or over curing. This would be manifest as little to no puff of the print on the underside or causing the puff to explode and collapse or not adhere to the fabric on the over cured side.

To avoid unwanted results as far as possible, it is best to experiment printing with PERMASET Puff Paste prior to starting your final production run.

Puff Printing is a relatively easy way to add interest to your prints and provides you with another customisation option. If you’d like to try puff printing, you can purchase PERMASET Puff Paste through many of our PERMASET resellers worldwide. Click here to find your closest PERMASET Stockist.

Alternatively, you can purchase PERMASET Puff Paste from our PERMASET Online Shop in Australia Happy printing with PERMASET Puff Paste. Please share the love by sending us some pics of your puff print creations so we can showcase your works on our @PERMASET_AQUA Instagram account. 😊

© COLORMAKER INDUSTRIES 2021

Subscribe to get the latest inspiration, news & advice direct to your inbox

More articles

@imearthie

@imearthie

Clothing label I’m Earthie shares how they strive to be a truly sustainable brand

Clothing label I’m Earthie shares how they strive to be a truly sustainable brand