With over 60 years of manufacturing experience, Colormaker Industries is recognised globally by both the fine artist and professional printing trade as the premier manufacturer of textile screen printing inks

Discover our water-based inks & paints

PERMASET AQUA®

Discover Permaset Aqua, eco-friendly water-based screen print inks for vibrant, long-lasting, durable & soft prints. Explore a wide range of colours for your screen printing projects.

PERMASET SUPERCOVER®

Experience unmatched opacity with Permaset Supercover inks. Ideal for printing dark fabrics and intense colour saturation in your screen printing designs.

PERMATONE®

Discover Permatone colour-matching set of textile inks, designed for professional screen printers. Match corporate colours on a range of fabrics.

AQUATONE®

Aquatone inks offer eco-friendly, water-based screen printing in a colour-mixing set for printing on paper, board, wood, some plastics, glass & leather.

PERMAPRINT® Premium

Explore Permaprint Premium, a top-tier water-based screen printing ink for exceptional results when printing on paper, board, wood, some plastics, glass & leather.

PERMACRYLIK®

Discover Permacrylik vibrant acrylic paints,for murals and the decoration of Film, Theatre and TV sets as well as installations and sign-writing.

Browse our store and purchase PERMASET Inks & accessories online

Projects, tips & ideas to keep you inspired

@heyreflecto

@heyreflecto

Meet HEY REFLECT’O and see how PERMASET Ink has helped them create their vision

Meet HEY REFLECT’O and see how PERMASET Ink has helped them create their vision

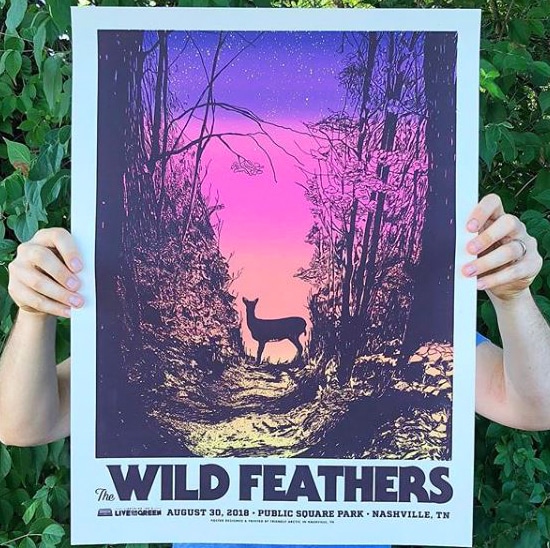

@friendlyarctic

@friendlyarctic

Read about sustainable screen printer Friendly Arctic’s journey from humble beginnings to its success today

Read about sustainable screen printer Friendly Arctic’s journey from humble beginnings to its success today

Get more from your PERMASET Ink

Help Centre

Whether you’re a beginner or a trade printing expert, we have the answers and how tos for you.

PERMASET Inks for Trade Printers

See how PERMASET Inks are used in the industry by Trade Printers.